WHAT WE DO

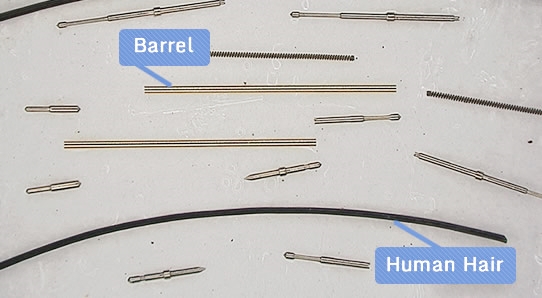

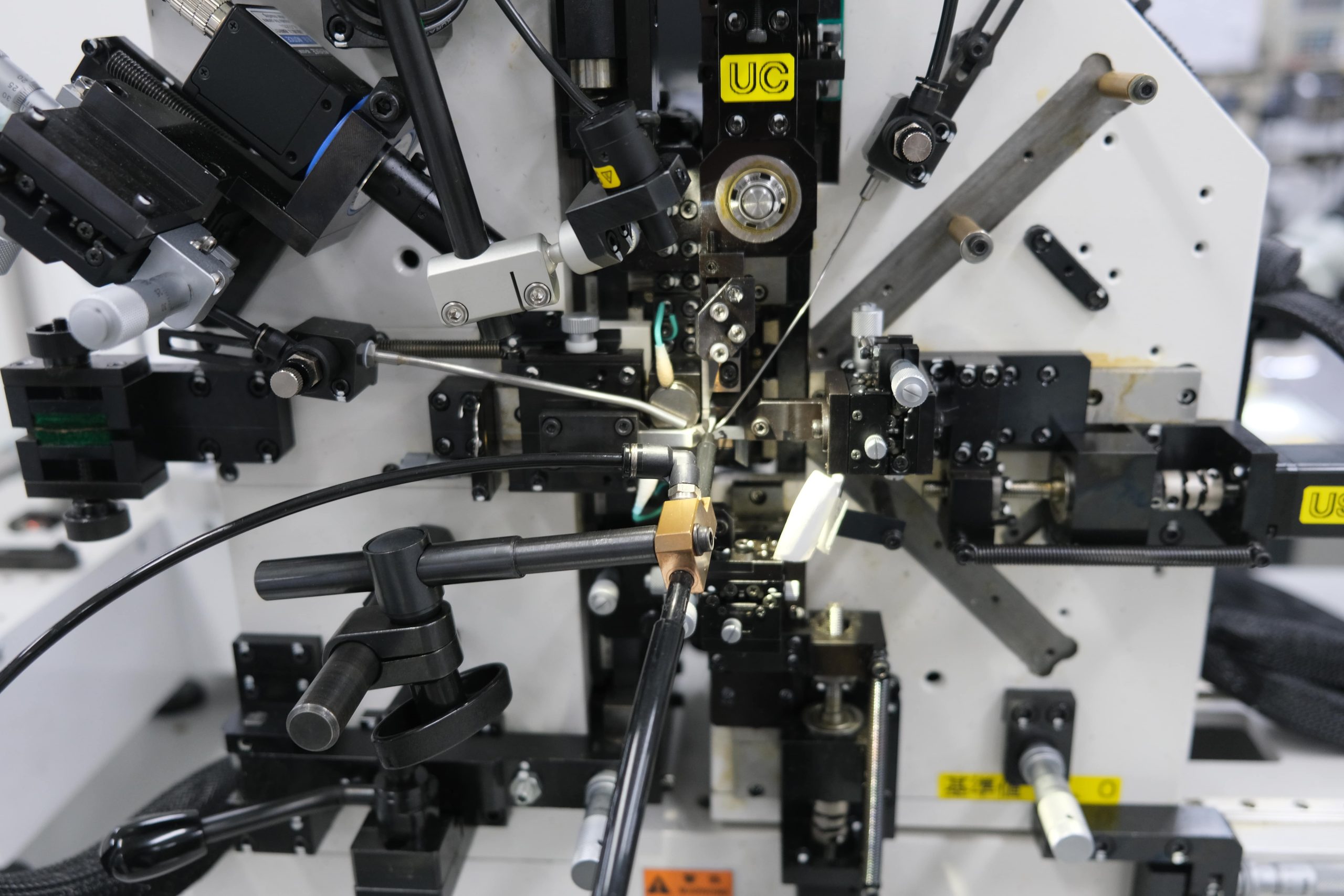

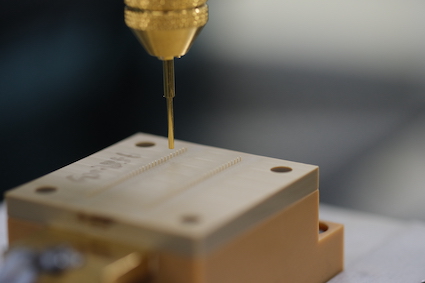

Spanning from Precision Machining to injection molding, Plating/Coating and Assembly,

Our Comprehensive Manufacturing Process guarantees top-tier products within the shortest production and delivery lead time by ensuring utmost customer satisfaction.

100% In-house Manufacturing